Rectangular gyratory screener and round gyratory vibrating screen

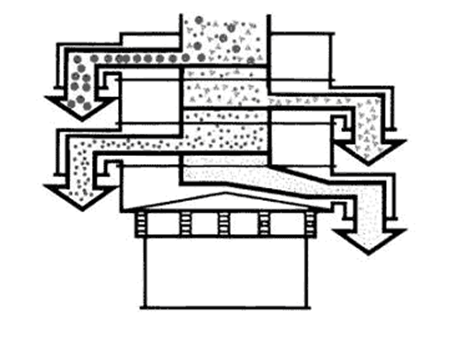

- Round gyratory vibrating screener feed material flow motion as following

From above pictures, the inlet of round gyratory vibrating screener is in the center of top cover, so the bulk material will be feed from the center of the screener, and it also will fall down on the center of the screener mesh

The bulk material motion path as following:

The bulk material motion path as following:

The material will flow toward the edge of the screener box from the screener box, so the material flow path distance only a little longer than the 1/2 of the screener mesh diameter, for example, the screener diameter is 2m, the material movement path distance may only 1.2m, it is much shorter than 2m, so the screening path is shorter than the screener deck diameter when adopt round gyratory vibrating screen, and the material flow speed is not high.

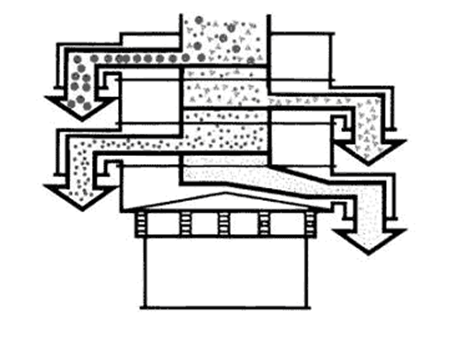

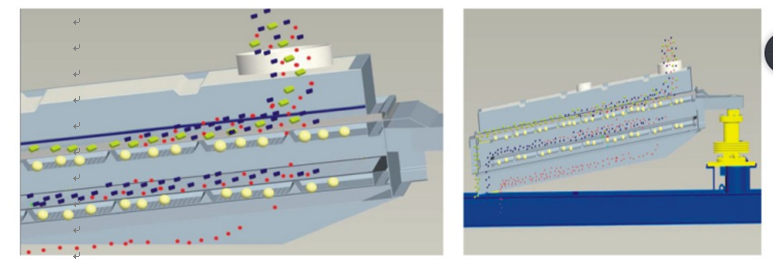

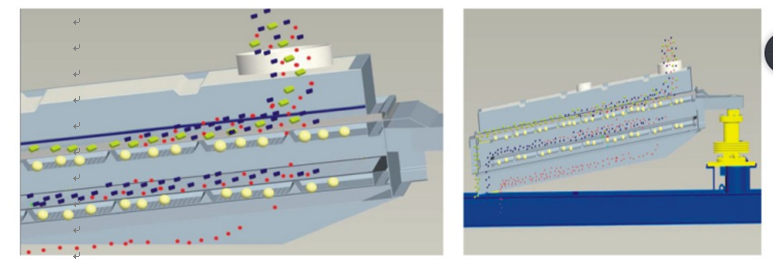

- Rectangular gyratory screener feed material flow motion as following

From above pictures, the inlet on one end of the top cover, so the material will be feed from one end of the screener box, and discharged from another end of the screener box

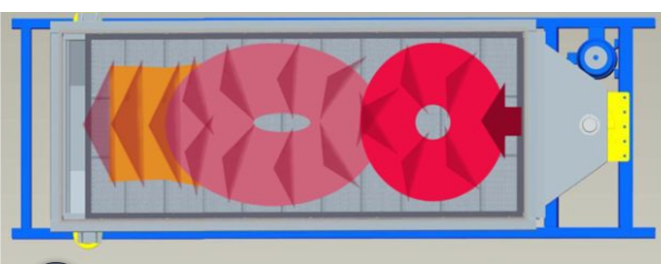

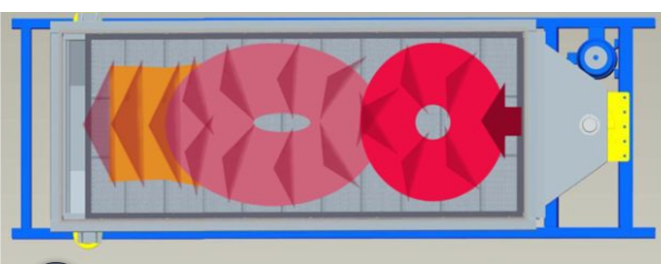

The material will flow toward the end of the outlet from the inlet, the material movement path will be along the whole length, and the material will to the gyratory motion along with the screener box, so the fact material moving path distance will be much longer than the screener box, for example, the side door access gyratory screener area is 1.2m*1.9m, the material flow moving path distance will be much larger than 1.9m, it is even 2 times of 1.9m, and the stroke of the screener is 60mm-80mm, the moving speed is higher, that is why the same side access door gyratory screener mesh area is 3-5 times of same area of round gyratory screener, for round gyratory vibrating screener, the material along could use the 1/2 of diameter of the screener mesh, but for the side access door gyratory screener, it could use even 2 times length of the gyratory screener mesh length, and have much higher movement speed

The material will flow toward the end of the outlet from the inlet, the material movement path will be along the whole length, and the material will to the gyratory motion along with the screener box, so the fact material moving path distance will be much longer than the screener box, for example, the side door access gyratory screener area is 1.2m*1.9m, the material flow moving path distance will be much larger than 1.9m, it is even 2 times of 1.9m, and the stroke of the screener is 60mm-80mm, the moving speed is higher, that is why the same side access door gyratory screener mesh area is 3-5 times of same area of round gyratory screener, for round gyratory vibrating screener, the material along could use the 1/2 of diameter of the screener mesh, but for the side access door gyratory screener, it could use even 2 times length of the gyratory screener mesh length, and have much higher movement speed